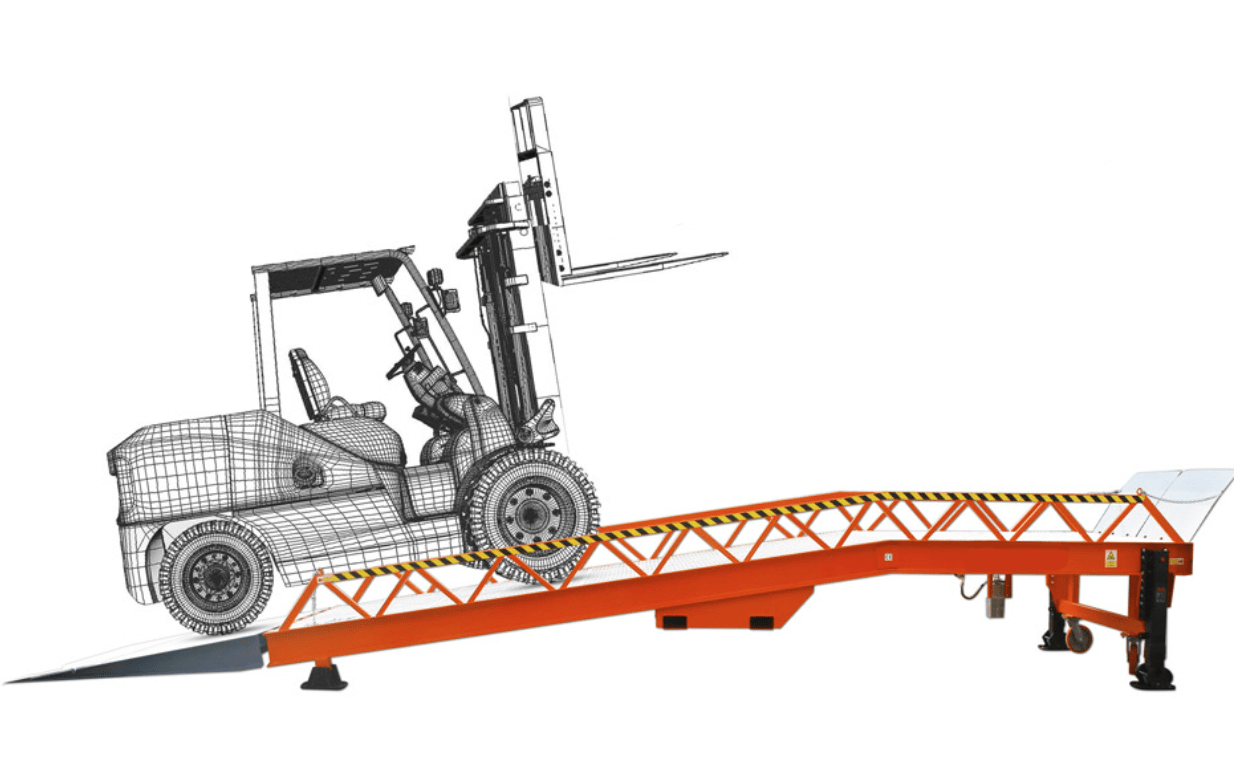

Loading ramps and warehouse equipmentDescription: Industrial ramps have the crucial role of facilitating the efficient loading and unloading of goods. These structures are designed to withstand heavy loads and allow vehicle access to storage or production areas. Industrial ramps are essential in logistics, optimizing workflows and ensuring security in the handling of goods. Auto ramps are designed to ensure the lifting of cars: auto ramps, elevators Applications: Available in a wide range of variants for different applications: loading ramps (mobile, fixed, level access, [...]

Packaging solutions, Primary, Transport and logistics industry access ramps, elevator, fixed ramps, loading ramps, mobile ramps, rampe acces, ramps, telescopic ramps, warehouse, warehouse ramps

Aflati mai multe...