Transport & Handling Solutions

Transport solutions are dedicated to all industries, provide an efficient production flow, periodic change of different types of packaging, a good time, adaptability to production programs that require more products on a single line. Includes a variety of models with special surfaces and features, pleats, rollers, steel protectors, friction and antistatic surfaces that offer unlimited options to handle a wide range of products and transport activities.

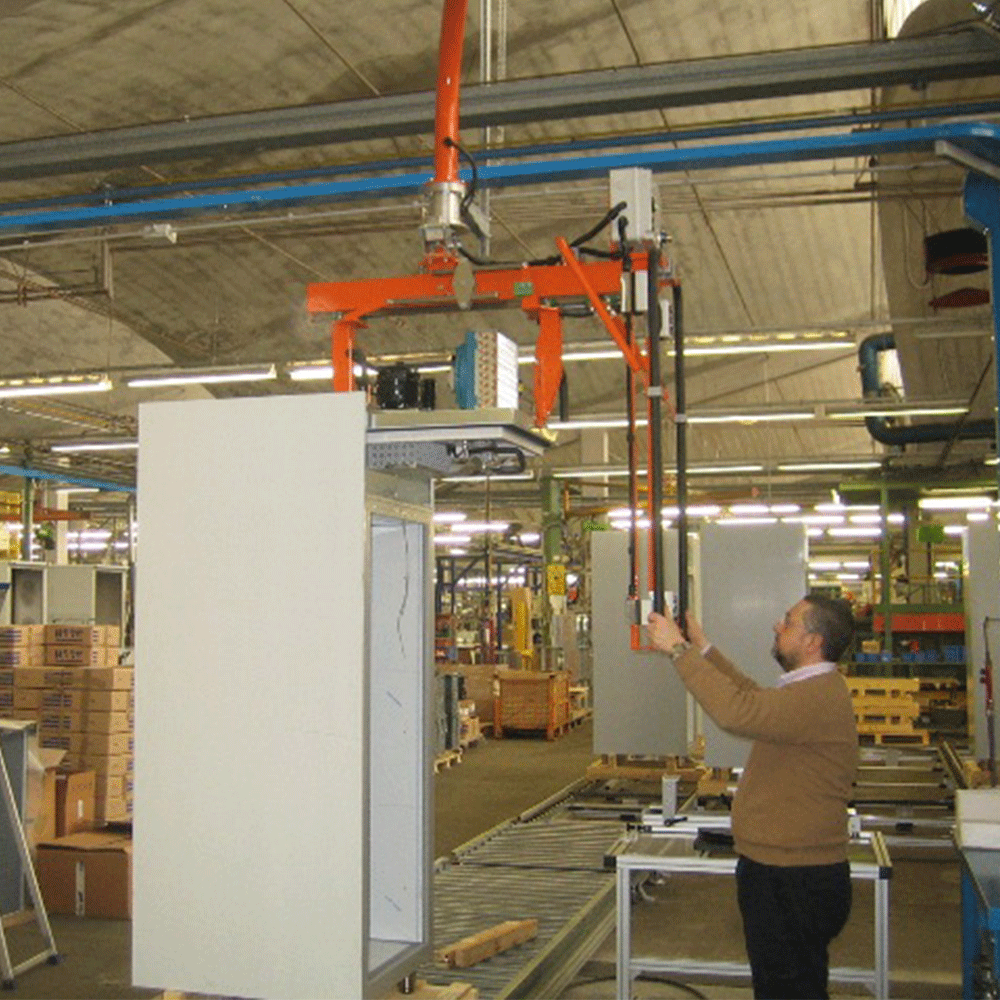

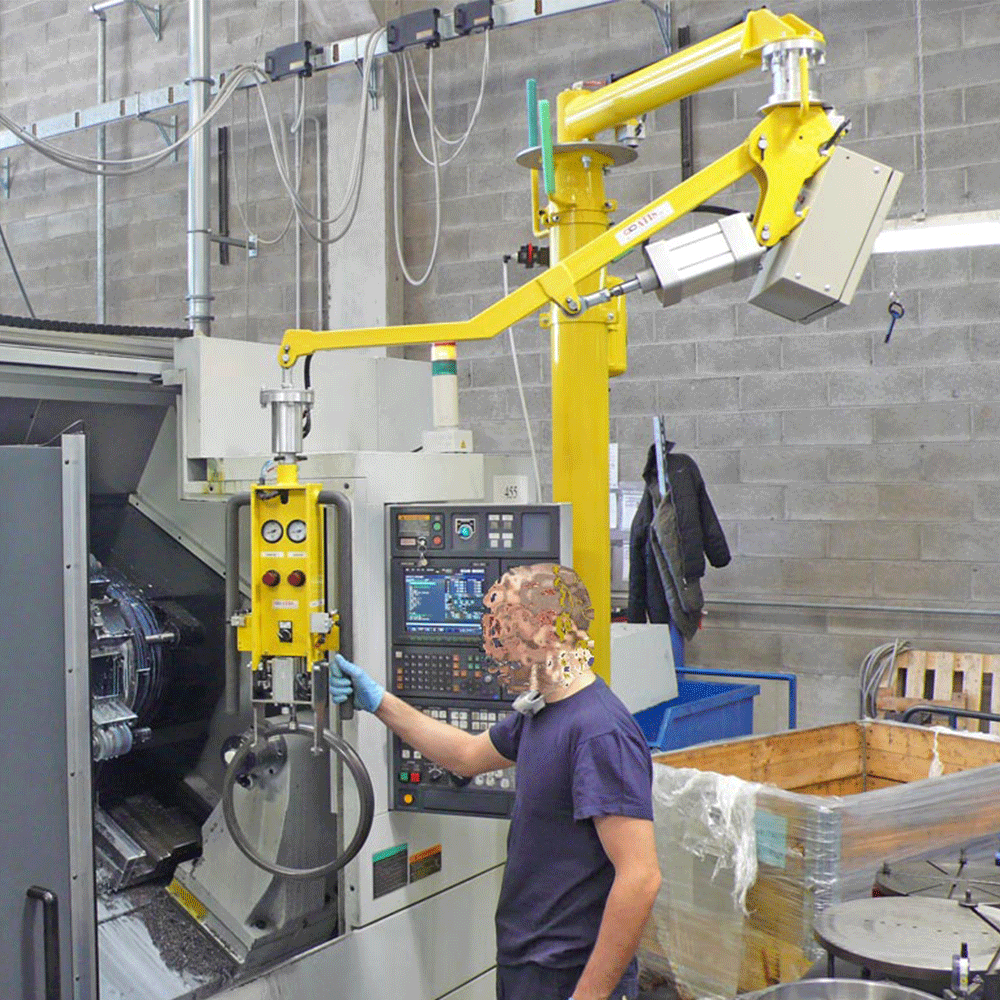

Intelligent handling solutions for handling various loads and heavy objects, for safety and ergonomics at work.

Conveyors

- Modular constructions that provide a high degree of flexibility and adaptability to production capabilities

- Compact design, ensures ergonomics of space and offers the possibility of designing complex routes, optimizing the occupancy of the space

- Transport systems are efficient for the automation and logistics industry

- Models with rollers, belt, chain, spiral or conveyor belt systems for pallet handling can be integrated

- For manufacturing (food, beverage, electronics etc), distribution or logistics sectors

- We design automated transport solutions for your specific activity and flow with the help of our specialized design, engineering, and software departments. Based on the extensive experience we have (more than 15 years) and the solutions developed with proven efficiency, we will ensure that the proposed solutions maximize the operational performance of your lines!

Conveyors

- Modular constructions that provide a high degree of flexibility and adaptability to production capabilities

- Compact design, ensures ergonomics of space and offers the possibility of designing complex routes, optimizing the occupancy of the space

- Models with rollers, belt, chain, spiral or conveyor belt systems for pallet handling can be integrated

- For manufacturing (food, beverage, electronics etc), distribution or logistics sectors

- We design automated transport solutions for your specific activity and flow with the help of our specialized design, engineering, and software departments. Based on the extensive experience we have (more than 15 years) and the solutions developed with proven efficiency, we will ensure that the proposed solutions maximize the operational performance of your lines!

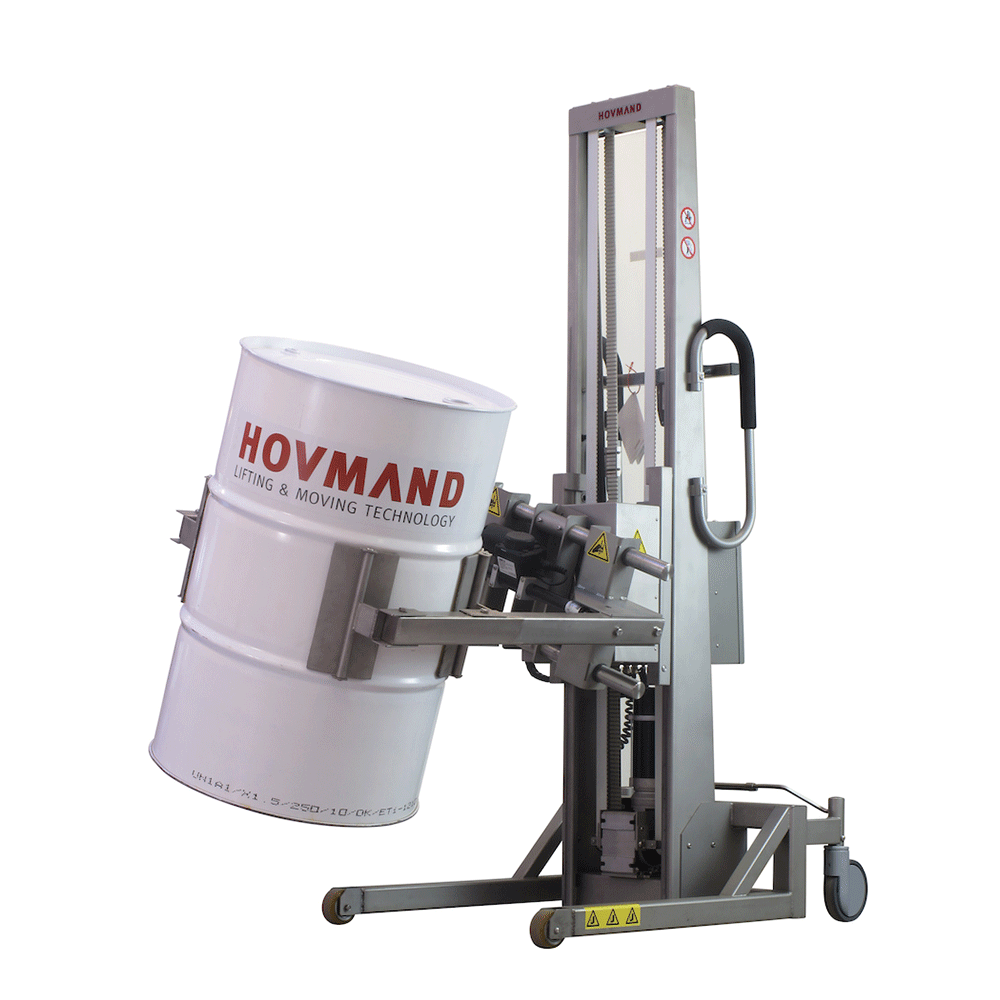

Electric lifting devices

A wide range of options for lifting and moving many heavy goods – solutions that protect employees, safe, flexible, and mobile: lifting trolleys, stainless steel lifting trolleys, lifters for kitchens and bakeries, wheel trolley lifters, lifting tools.

Applications in production spaces, warehouses, and logistics, pharmaceutical & cosmetics industry, chemical industry, food industry, canteen kitchens and bakeries, additive production, car repair garages, etc.

Benefits:

Safety – Reduced risk of accidents – for your company and your employees.

Ergonomics – Ideal solutions to improve your corporate health management.

Efficiency – Improve processes and make better use of resources.

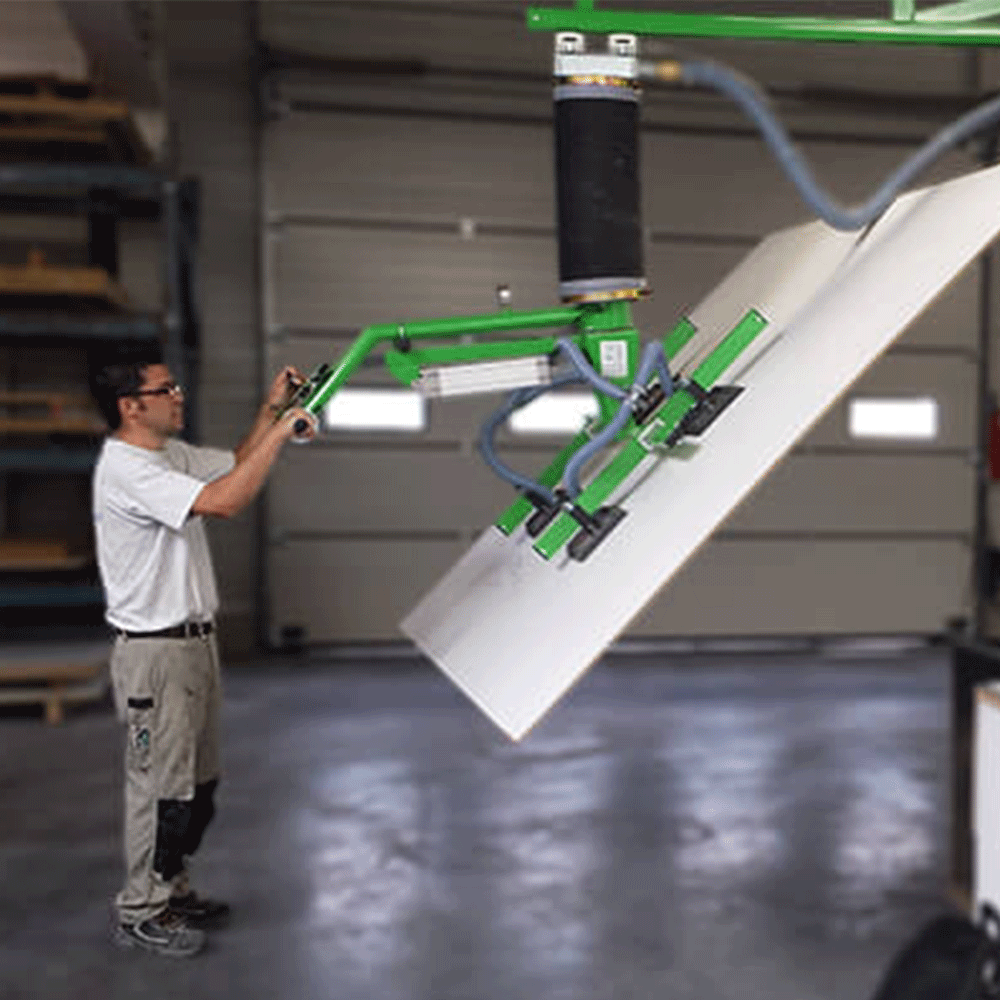

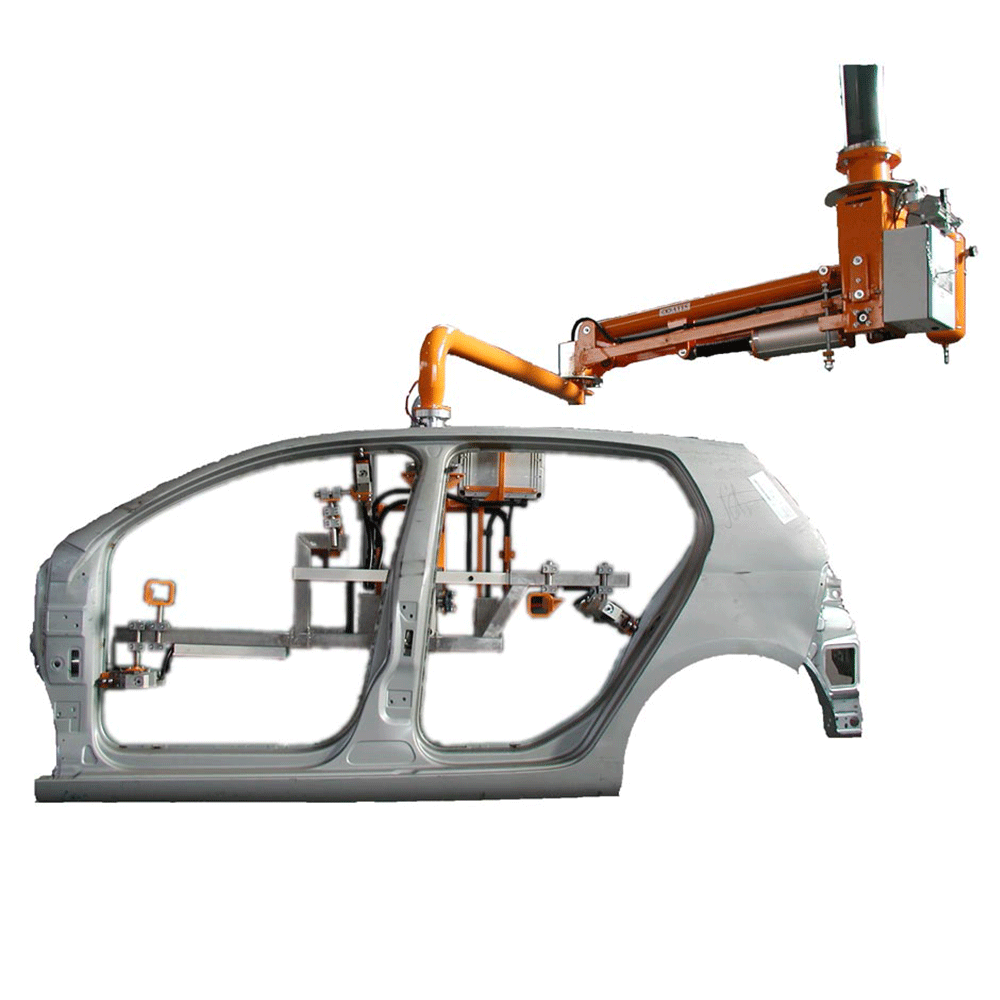

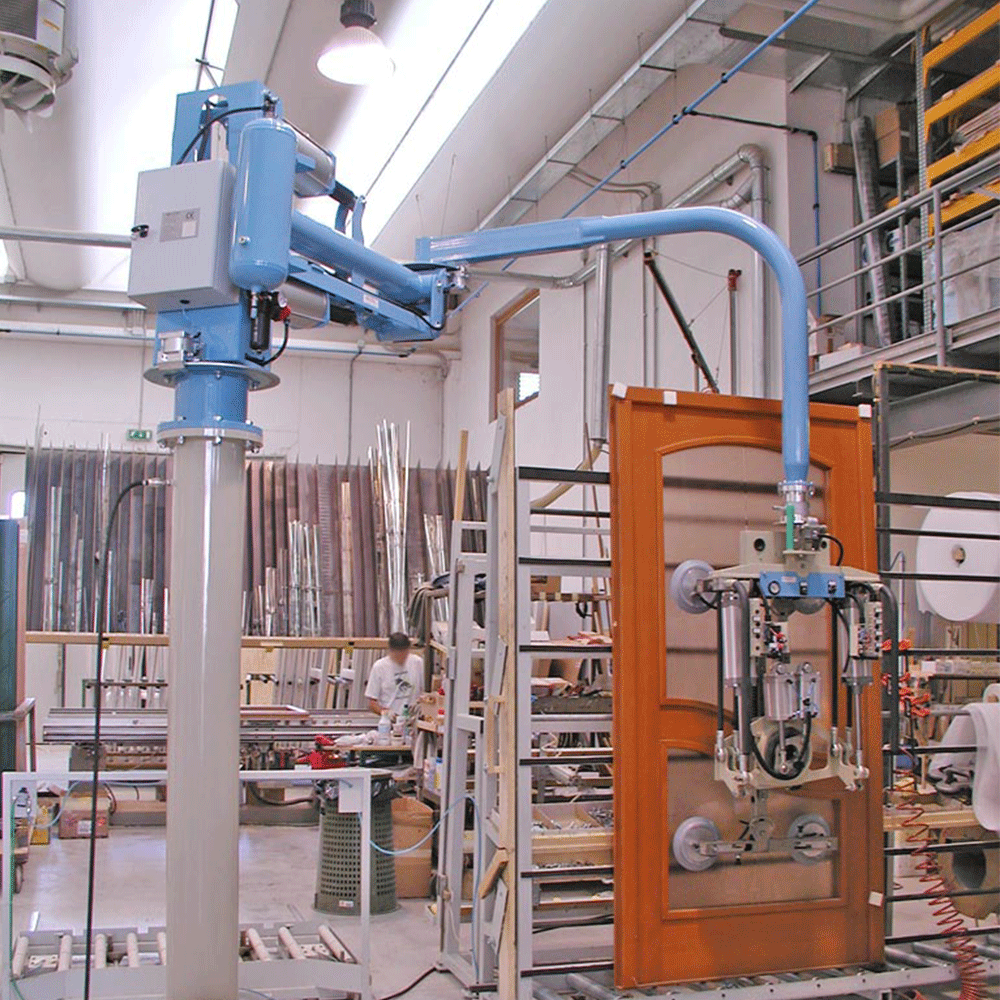

Vacuum manipulators

The equipment adapts to all sectors of activity to maximize productivity, product safety and at the same time limit the risks of accidents at work (logistics, wood industry, chemical and pharmaceutical, agricultural & food, construction materials industry, wine industry).

Take a look at some solutions:

Pneumatical industrial manipulators

Pallet changers

Pallet changers have the following benefits:

- Compliance with hygiene rules: replacing wooden pallets (delivery area) with aluminum pallets (production area)

- Reducing delivery costs, by using cheap pallets, considering that in general the pallets with which products are delivered are not returned. The plastic pallet is too expensive to be used as a delivery pallet, the pallet changers allow replacing the plastic/aluminum pallet (from the production area) with a wooden pallet.

- replacement of damaged pallets: during the processes of loading, unloading or reloading the goods, damage to the pallets may occur caused by the blades of a forklift or accidental hits during handling.

Shuttle

- Automated, flexible and performance platforms

- Can be deployed in multifunctional applications

- Have multiple navigation systems

- Solutions designed to be used near operators and offer low maintenance

- Applications in transport, logistics, automotive

Shuttle

- Platforme automatizate, flexibile si performante

- Pot fi implementate in aplicatii multifunctionale

- Au multiple sisteme de navigatie

- Solutii concepute pentru a fi utilizate in apropierea operatorilor si ofera intretinere redusa

- Aplicatii in transpoturi, logistica, automotive

Loading ramps and warehouse equipment

Industrial ramps have the crucial role of facilitating the efficient loading and unloading of goods. These structures are designed to withstand heavy loads and allow vehicle access to storage or production areas. Industrial ramps are essential in logistics, optimizing workflows and ensuring security in the handling of goods.

Auto ramps are designed to ensure the lifting of cars: auto ramps, elevators

Applications:

Available in a wide range of variants for different applications: loading ramps (mobile, fixed, level access, built-in, etc.), warehouse equipment (loading platforms, bridges for access to containers, lifting table with system ). hydraulic shears, etc.), customized equipment

Strengths:

- Comfort in use and reduced time dedicated to loading and unloading

- You can fall in any weather conditions

- They allow good handling, even in small areas

- Loading and unloading become 2-3 times faster