Industrial robots automation solutions

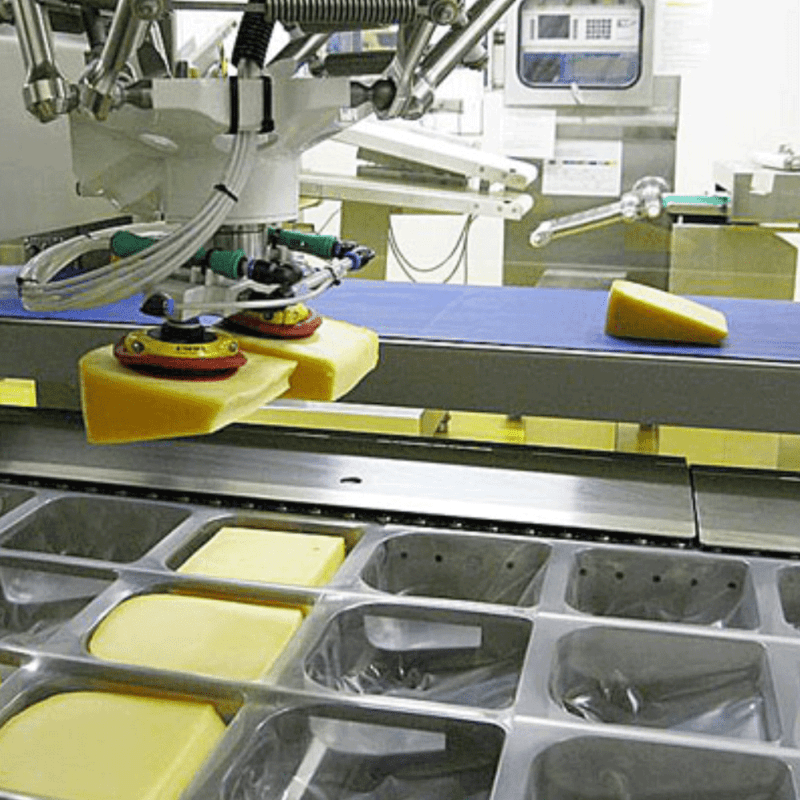

Palletizing/depalletizing with industrial robots

When automating the palletizing/depalletizing stage is the only way to get the efficiency you need, palletizing/depalletizing solutions with industrial robots are the best answer.

Robust, designed, and built robots to ensure 100% of the operating cycle and faster cycle times. Capable of handling large and very large payloads, palletizing/depalletizing solutions with industrial robots are the ideal option for a multitude of standard or mixed, complex operations.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

Palletizing/depalletizing with industrial robots

When automating the palletizing/depalletizing stage is the only way to get the efficiency you need, palletizing/depalletizing solutions with industrial robots are the best answer.

Robust, designed, and built robots to ensure 100% of the operating cycle and faster cycle times. Capable of handling large and very large payloads, palletizing/depalletizing solutions with industrial robots are the ideal option for a multitude of standard or mixed, complex operations.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

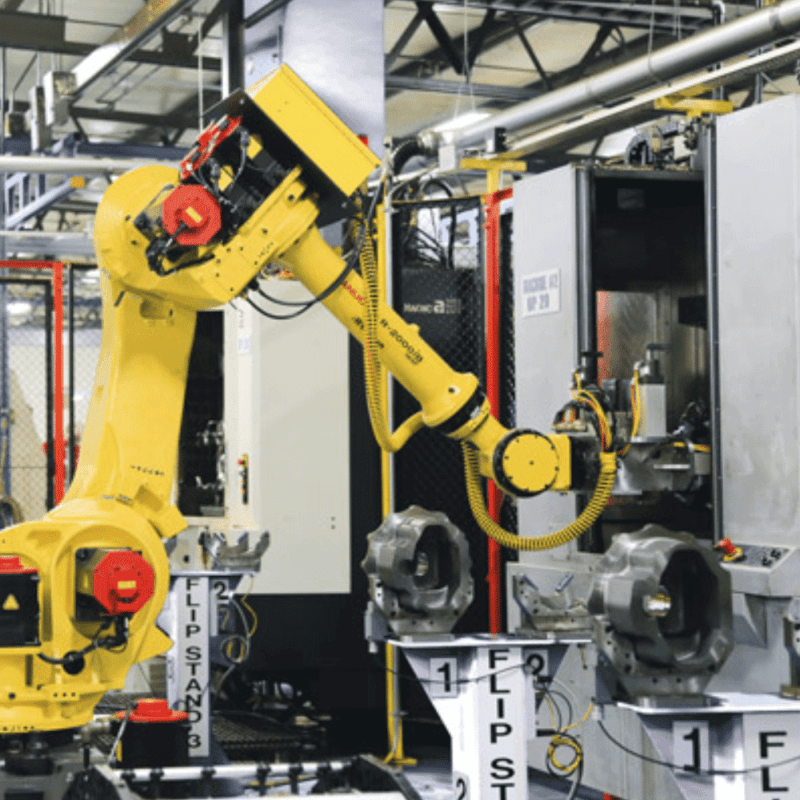

Machine tending with industrial robots

Industrial robots for machine tending streamline a variety of operations, such as injection molding, cutting, machining, and assembly of small parts, etc. Taking into account the limited space that exists in the vast majority of production spaces, compact solutions are available, industrial robots with a small footprint.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

Machine tending with industrial robots

Industrial robots for machine tending streamline a variety of operations, such as injection molding, cutting, machining, and assembly of small parts, etc. Taking into account the limited space that exists in the vast majority of production spaces, compact solutions are available, industrial robots with a small footprint.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

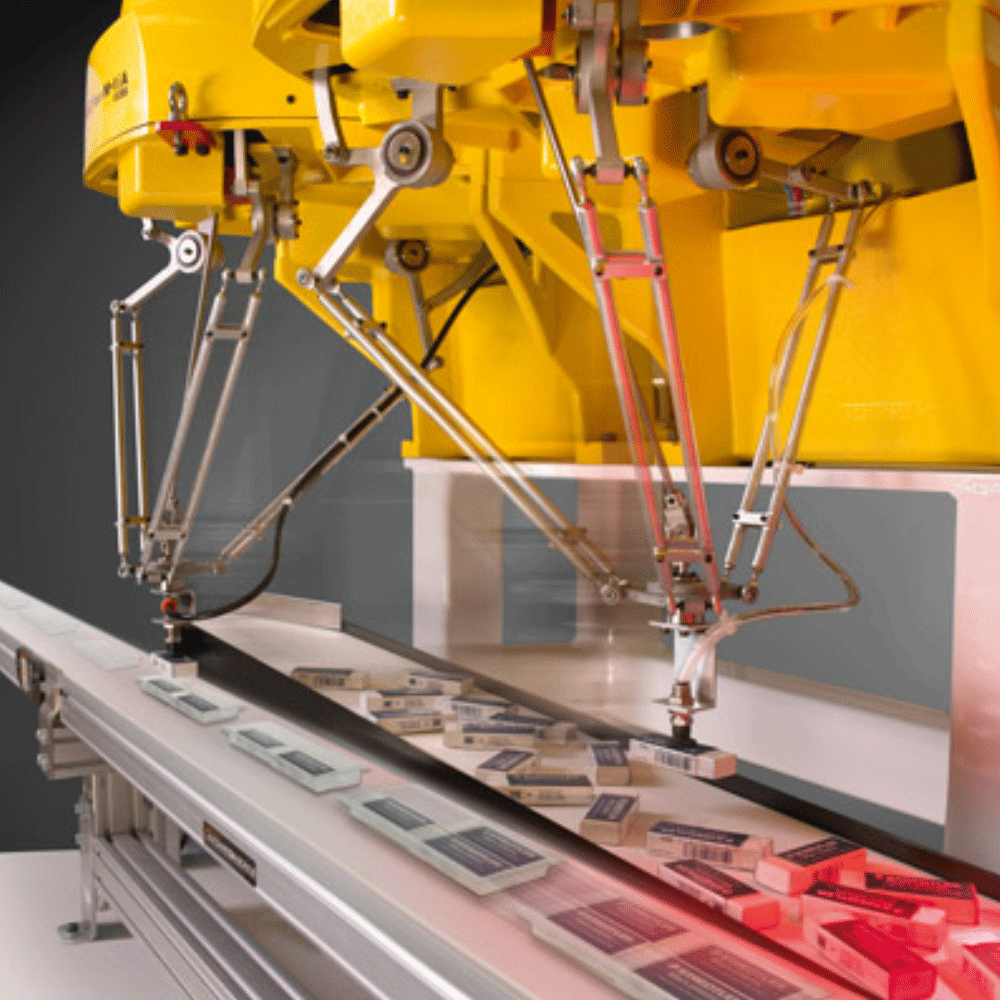

Handling and sorting, packaging with industrial robots

Industrial robots can handle, sort, and package products with different shapes, consistently, at the same quality, and at high speeds, without breaks.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

Handling and sorting, packaging with industrial robots

Industrial robots can handle, sort, and package products with different shapes, consistently, at the same quality, and at high speeds, without breaks.

For a simple and fast integration, our team will ensure the complete management of the project, from consulting, design to the integration in the production line and after-sales services, through our specialized design, service, and software departments.

Industrial robots maintenance

Let our experience help you avoid the common mistakes associated with caring for your robot. Contact us today for more information.

Industrial robots maintenance

Let our experience help you avoid the common mistakes associated with caring for your robot. Contact us today for more information.