Inspection and detection with vision systems

Products can break or become damaged during production. Inspecting for product integrity prior to packaging is critical to ensure customer satisfaction and protect brand reputation. Cognex identifies defects and rejects them before they reach the customer, protecting your company’s brand against the net effect of damaged goods while avoiding stoppages and downtime.

The benefits of vision systems in the product inspection:

- Detect damaged products

- Reduce costly downtime and manual intervention

- Avoid packaging mix-ups

- Preserve customer loyalty

Vision applications in product quality inspection:

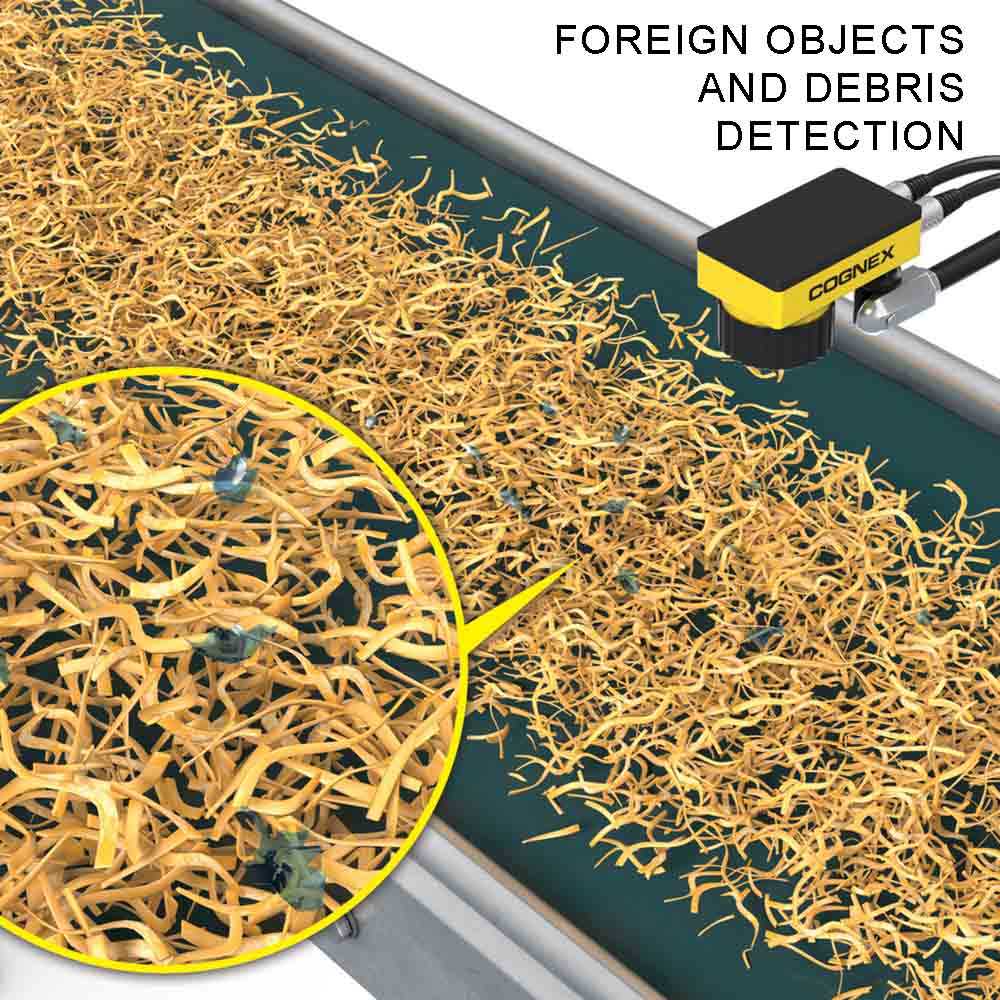

- Detect foreign objects and debris

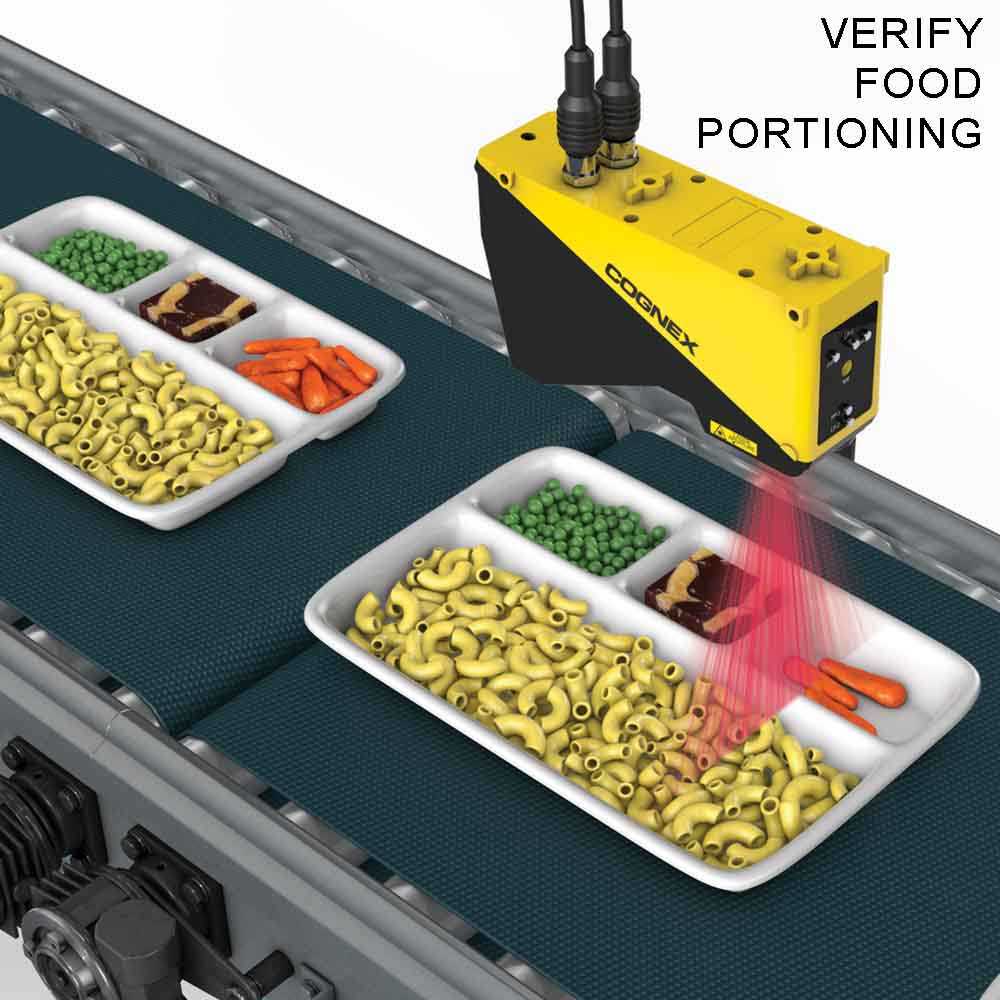

- Verify food portioning

- Match product to packaging

- Ensure consistent size, shape, color, and texture

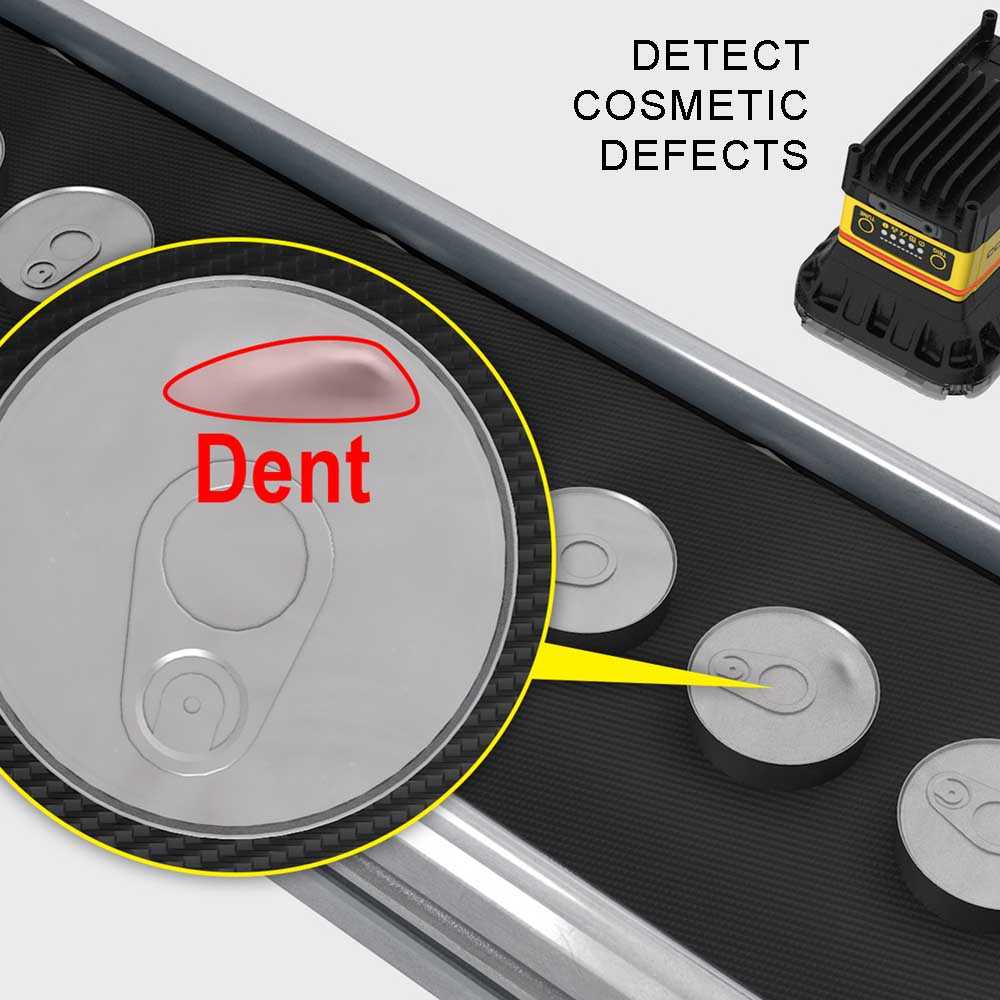

- Detect cosmetic defects

- Automate classification

Inspection and detection with vision systems

Products can break or become damaged during production. Inspecting for product integrity prior to packaging is critical to ensure customer satisfaction and protect brand reputation. Cognex identifies defects and rejects them before they reach the customer, protecting your company’s brand against the net effect of damaged goods while avoiding stoppages and downtime.

The benefits of vision systems in the product inspection:

- Detect damaged products

- Reduce costly downtime and manual intervention

- Avoid packaging mix-ups

- Preserve customer loyalty

Vision applications in product quality inspection:

- Detect foreign objects and debris

- Verify food portioning

- Match product to packaging

- Ensure consistent size, shape, color, and texture

- Detect cosmetic defects

- Automate classification